High temperature and high pressure tolerance: It can operate stably in high temperature hot water and high pressure conditions to ensure long-term reliability and safety.

Super corrosion resistance: 304 stainless steel material resists scale, oxidation and chemical corrosion, prolongs service life and reduces maintenance costs.

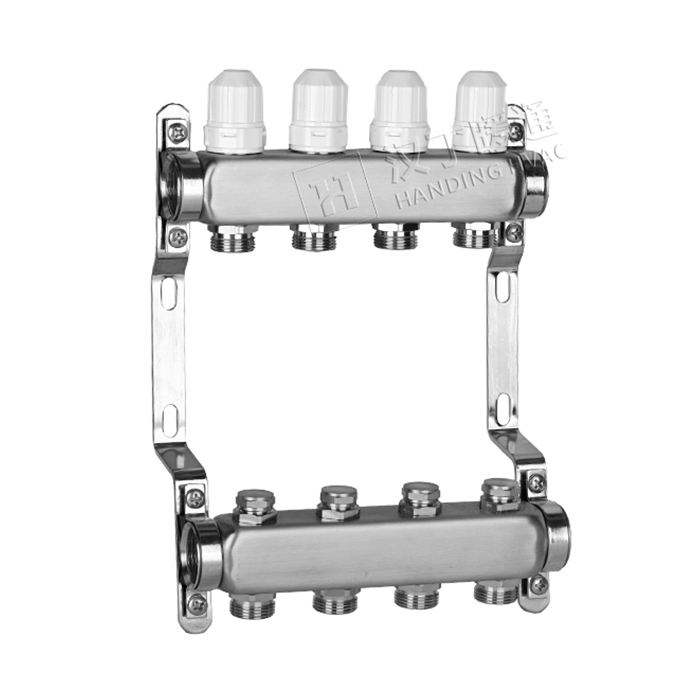

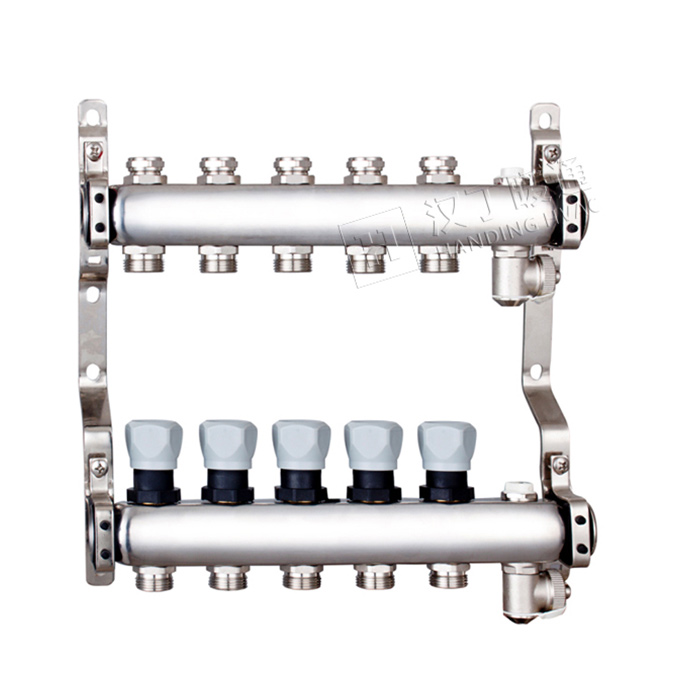

Eight-port efficient distribution: Multi-interface design supports complex pipeline layout, adapts to a variety of radiator connection requirements, and is easy to install.

Precision technology: Seamless welding and polished inner wall reduce flow resistance, optimize heat medium flow efficiency, and save energy and reduce consumption.