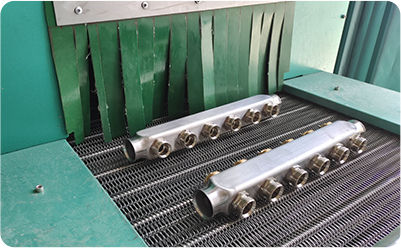

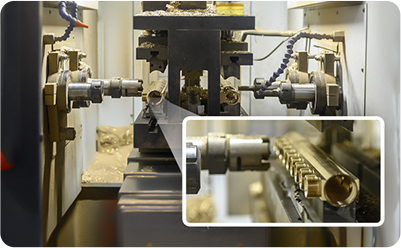

Raw Material

Material Test for every lotAll incoming brass deliveries are color coded by type, each lot is randomly selected for internal Testing which includes composition analysis and brass hardness tests.

GET A QUOTE