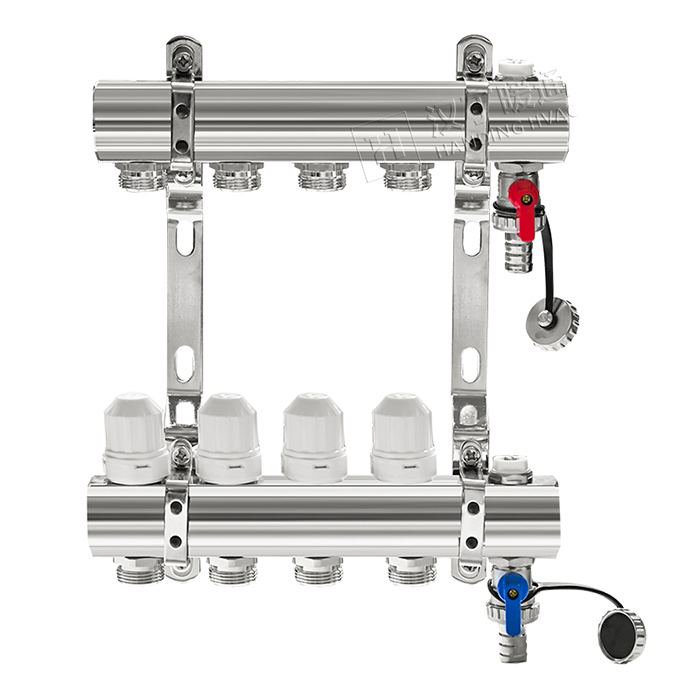

Flow monitoring and control: built-in mechanical flow meter, real-time display of medium flow rate, support intuitive adjustment, optimize heat energy distribution efficiency, and reduce energy consumption costs.

Dual exhaust valve redundant design: equipped with two independent exhaust valves, can quickly discharge the trapped gas in the pipeline, effectively avoid air blockage problems, and reduce efficiency loss or equipment damage caused by air accumulation.

Durable structure and convenient maintenance: chrome-plated surface enhances anti-corrosion ability, and precision brass casting process ensures long service life;